About us

The tagline of MatchID is “Metrology beyond colors”, offering the DIC system of the future where the main focus lies on the metrological aspects of the system, enabling quantitative results interpretation with integrated error assessment, material identification, model validation and modal analysis.

Created at university of Leuven to get profound insights into DIC

In 2008, the University of Leuven-Technology campus Ghent, Belgium, started developing an open, holistic DIC-platform. The major aim was to get a profound knowledge of the measurement capabilities and uncertainties of DIC and how these transfer towards material identification and model validation.Since then, this application has been implemented and proof-validated by over 200 academic institutions worldwide.Moreover, joining forces with one of the co-inventors of the VFM (Virtual Fields Method) enabled us to incorporate this material identification technique directly in our software portfolio.

Supporting design and development

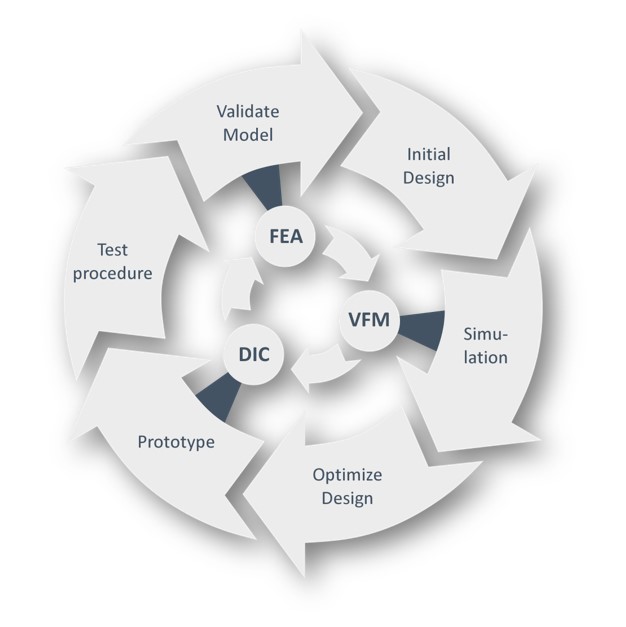

By structurally embedding VFM, MatchID goes well beyond DIC by offering material identification tools.

These parameters then serve as a basis for Finite Element modeling (FEA), leading to a universal challenge in engineering: validation of simulations.

MatchID has developed an FE validation module that creates a full-field, point-to-point relation between simulation (FE model) and test (DIC result). This module thus allows for structural validations of simulations.

Moreover, MatchID now integrates with Simcenter testlab providing profound solutions for modal analysis.

Learning from and teaching to academics and engineers

MatchID is as much a software platform as it is a community of engineers and scientists, finding ways to optimize research experiments. Our customers show us the way to keep pioneering and keep pushing DIC forward. We train and transfer knowledge via our annual DIC-courses, wiki, webinars and research program support.